Radiation Containment Facility

Hospital Oncology Unit

- Reduced construction time as there were no reinforcing bar cages to build and install

- Reduced number of workers on site as there was no formwork nor rebar to install

- Reliable concrete pour and compaction as there were concerns about ensuring sound concrete towards the bottom of the heavily reinforced walls

The ready-mix concrete supplier developed an excellent mix that enabled 40 kg/m3 of hook-end steel fibre 65/60 to be added. To control heat of hydration and obtain a dense concrete mix a high proportion of non-cementitious binder was used together with cement.

The project was a successfully completed and tested using radiation detection equipment. The new oncology unit easily met the stringent requirements of the client. This project was completed in 2009 and set a precedent. We understand that all new oncology units constructed in Australia since then have adopted fibre reinforced concrete.

It should be noted, very thick walls and slabs constructed of fibre reinforced concrete would not only contain radiation but would also be highly resistant to blast forces and severe impact loads. This is due to the high energy absorption capacity of FRC compared with conventionally reinforced concrete.

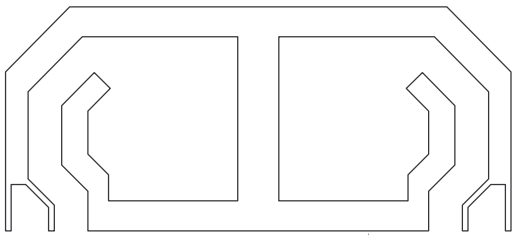

This diagram shows the maze-like nature of the oncology unit to avoid radiation leakage through openings.

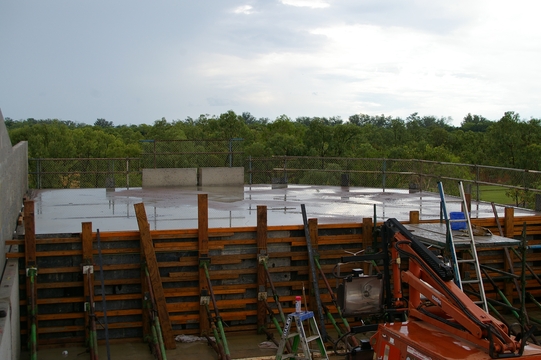

A view of the top of the walls about to be poured. The precast panels acting as lost formwork for the walls and roof slab are visible. Props have been placed at the top are propped at the top and mesh has been placed over the openings as a safety measure to prevent accidental falls and equipment being dropped.

This is the first wall that was poured. All pours were completed during night-time hours to avoid the heat of daylight hours in the tropical climate.

As the roof slab is very thick there was no need for any conventional reinforcement, nevertheless a bottom layer of light mesh was adopted to ease any concerns about tension capacity of the concrete.

A boom lift was utilised to deliver the pumped concrete and apply compaction equipment. As the SFRC had plasticizer the slump was quite low and did not require a great deal of compaction. The "tide marks" on the walls indicate the concrete staging adopted by the builder.

Water was applied to help with curing