Steel Fibre

There is a big range of steel fibres available. Performance and cost vary, usually with a correlation; higher performance usually means a higher cost. Fortunately there is enough information available to make a cost/benefit analysis for most types of structures.- End anchorage - sufficient to maintain high tension in the fibre even with substantial crack openings

- Steel strength - to prevent fibres snapping, especially if they have good end anchorage, usually 1000 MPa to 2000 MPa

An optimised steel fibre is one where end anchorage is maintained for a substantial length of the pull-out phase and steel stress during pull-out exceeds 80% of the yield strength. Anchorage and steel stress depend upon the concrete mix. Lower strength concrete will not mobilise fibres as well as higher strength concrete. Aggregates are also known to have an effect on fibre anchorage.

With these two fundamental parameters in mind, manufacturers have rightly adopt high strength steel with a range of end anchorage types. They have also adopted aspect ratios - length to diameter - that usually exceed 40 and tend to optimise in the range 50 to 80.

The two main problems with using fibre are:

- Workability - there is a significant reduction in slump with the addition of fibres as well as an upper limit of fibre content beyond which it is impractical to place concrete. Good mix design and plasticisers will help alleviate this problem.

- Dispersion - randomness is important except where alignment can be beneficial. Fibres that form balls and become ineffective are a nuisance, as are regions of the concrete matrix without many fibres. Ways to overcome this problem are to have end anchorages that do not hook together and/or gluing the fibres together with a glue that gradually dissolves in the concrete allowing the fibres to disperse during mixing.

High performance fibres

Based on our research the most highly optimised fibres available today are:

|

|

Poor performance fibres

- Tests have shown that straight steel fibres with no hooks or end anchorage of any sort provide extremely poor performance, less than one tenth of the same fibre with end anchorage. In other words, almost useless.

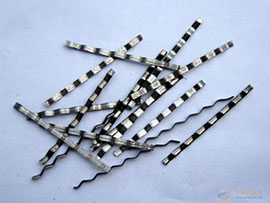

- Wave form fibres, such as the one shown below, suffer from having anchorage that is too good. This means the fibres snap at very small crack openings of approximately 0.2 mm to 0.5 mm. The purpose of adding fibres is to redistribute micro-cracks in the concrete matrix and provide post-crack strength that results in a softening curve. Steel fibres provide very little overall additional tensile strength to the concrete but have an important post-crack function. Hence these types of fibres should be avoided.

Middle of the range performance

There are many fibres that provide performance between the two

extremes mentioned above. Very high performance fibres tend to be

quite costly and for many (if not most) applications regular

hook-end or flat-end fibres would be quite adequate. The key is to

understand the purpose of the fibres for any given application and

the available concrete mixes.