Pavement Joints

Joints are very often a source of failure in pavements. Tests have shown that traditional dowels, such as 20 mm diameter rods, require quite large differential movements across the joints before the dowels are mobilised. This is due to the small bearing width of the dowel, just the diameter. The magnitude of the differential movement to mobilise the round dowels is such that the slab usually cracks before the movement can take place.Wider plate dowels are much more effective as much less

differential movement is required to mobilise the dowel.

Tests have also shown that steel fibre reinforced concrete can

transfer more load across a dowel (irrespective of dowel shape) than

plain concrete. The increase in load transfer is approximately 30-40%

depending on the concrete mix design.

|

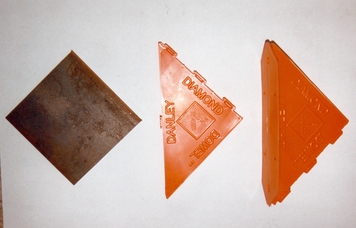

Example of the components of a

plate dowel. The plastic sleeve is nailed to the form-board of the first pour. After the concrete has cured and the form-board is removed, the square steel plate is inserted into the plastic sleeve. The the adjoining slab is poured. |

|

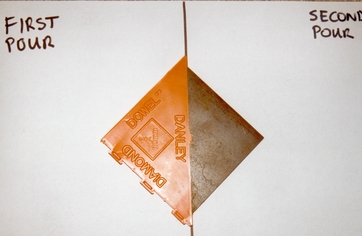

Concrete from the second pour surrounds and bonds to the

steel dowel plate. The plastic sleeve of the first pour allows

the joint to move apart while still providing a bearing

surface so the dowel can resist any differential movements

across the joint. The system has the advantages of much better control of the differential movement plus higher load transfer capacity of steel fibre reinforced concrete. |

|

Example of a dowel system that later becomes a joint. Note the concrete is poured over the dowel and completely surrounds the system. After the concrete has cured, the slab is saw-cut directly over the centre of the dowels. The saw-cut depth is to within 5 mm of the top of the dowels. The dowel are at approximately mid-depth of the slab, so the saw-cut is about half the depth of the slab. A crack initiator at the base of the slab and shrinkage forces the joint to occur at the dowel cradle. |

Disclaimer: Information in this website is provided for information only. There is no implied warranty

or claim to being "fit for purpose" and suitable for design. Anyone using the information does so entirely

at their risk and should satisfy themselves as to the veracity of the application.

This website and all the content contained therein is copyright ©

2026 protected.

Projects